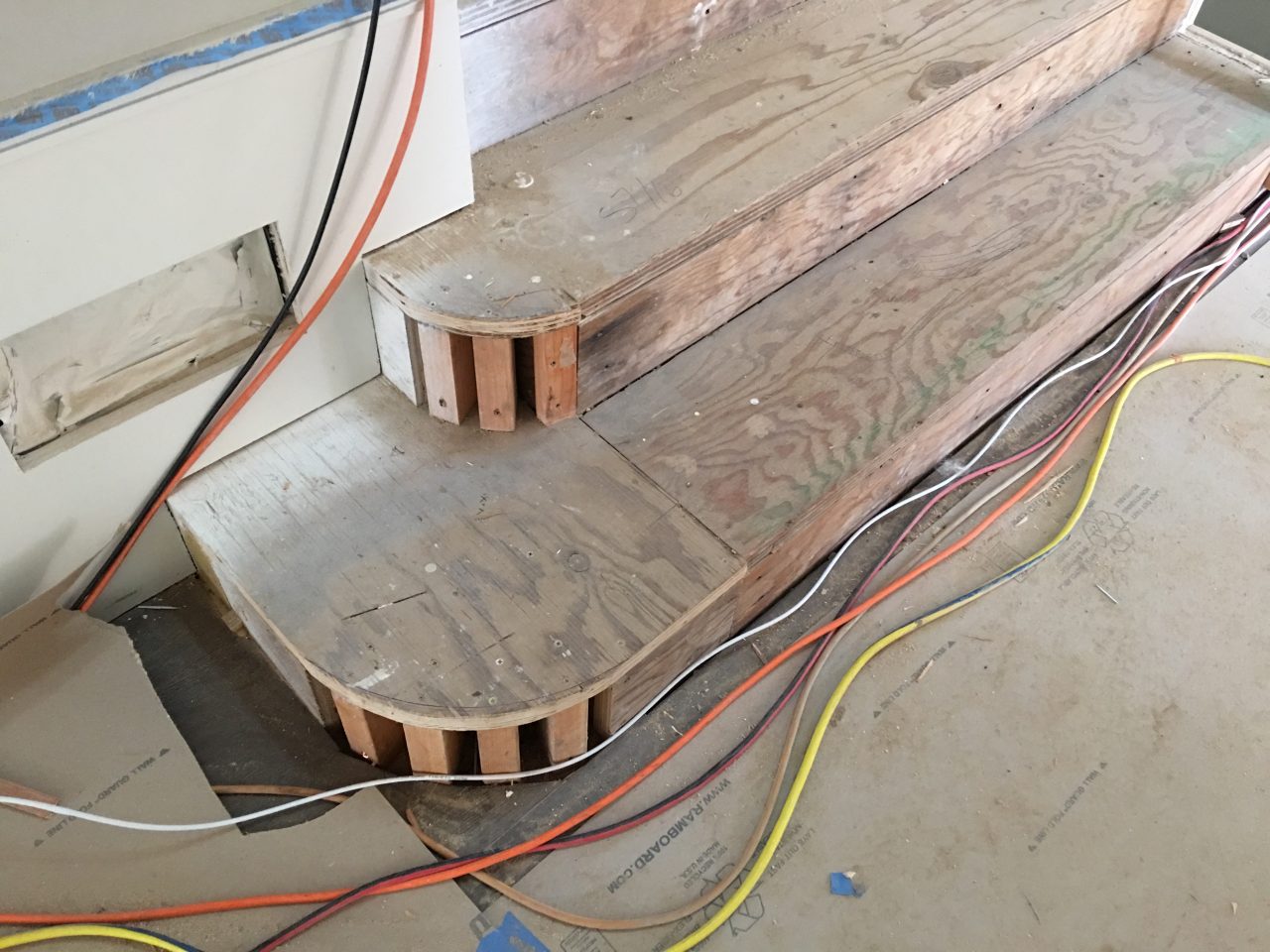

Our house, being a craftsman, is very angular. Pretty much everything is a right angle and there are almost no curves. Almost, because, at the bottom of our stairs, we decided to make the last two treads curved where they extend past the wall.

Here is a normal section of stairs.

On top goes the wood floor + nosing, and on the face is the riser. Here is the material we are using for the risers, 3/4″ poplar.

Is pretty simple to rip a riser down to the proper height, and cut it to length. But what about the two curved steps?

The solution is to use multiple layers of 1/8″ plywood, with the last layer being finished with a thin layer of paint-grade wood.

The carpenters first trace the curve of the steps, and cut a template.

From the template, they build a block form to fashion the curved section around.

Then, they bend each piece around the template, applying glue between the layers.

Once the glue dries, the piece will be fixed in that shape.